Cooling meters experience a unique challenge regarding condensation, especially in hot and humid environments. See how you can get protection against this issue with a particularly designed cooling meter solution from Kamstrup.

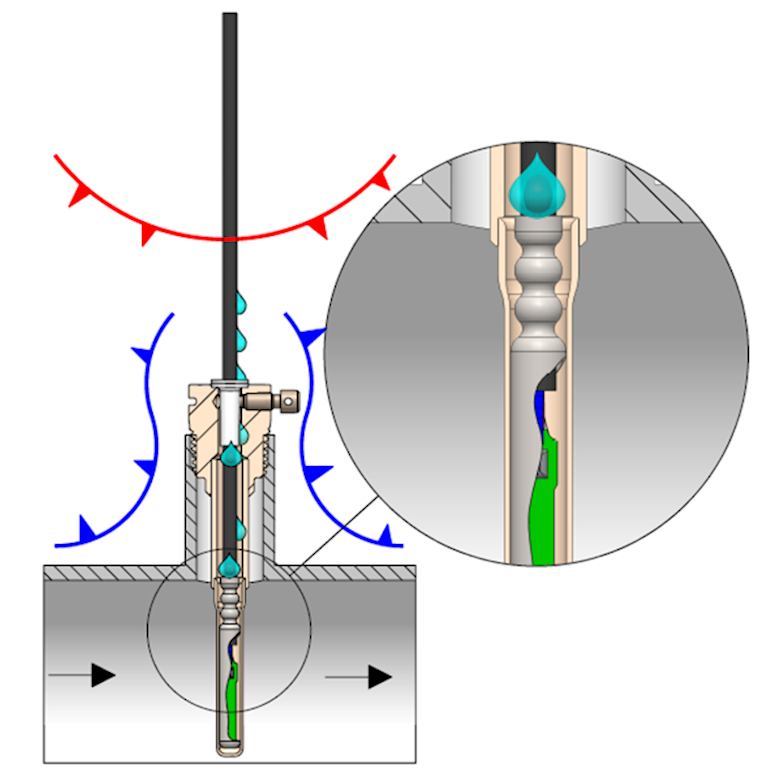

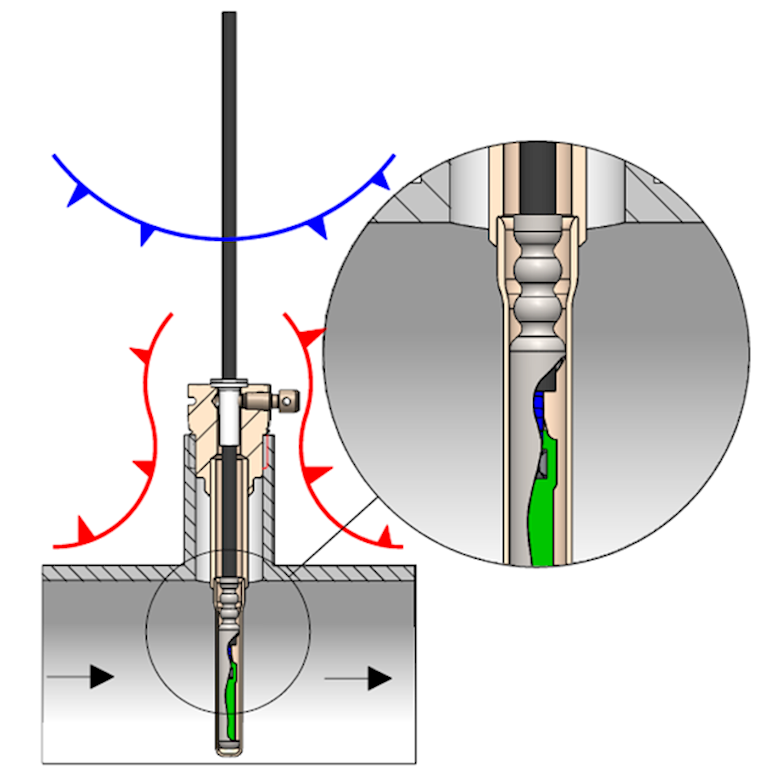

Figure 1: Temperature sensor used on a cooling meter application

Cooling meters have a special challenge regarding condensation. When hot air with relatively high humidity comes into contact with a cold surface, the air is cooled down and the moisture in the hot air forms condensation on the cold surface. As shown in the above figure, the condensation is typically able to intrude any electronics in contact with the pipes with chilled water. This may eventually lead to short circuits or corrosion problems which have a detrimental influence on the performance of a cooling meter and ultimately reduce the lifetime of the cooling meter. This is very different from what happens on a heat meter/thermal meter where the pipes are hotter than the surroundings as shown in the above figure to the right and therefore, condensation does not occur on heat meters.

Historically, the use of heat meters has been more widespread than the use of cooling meters. Therefore, many cooling meters on the market, popularly known as BTU meters, are actually meters that were originally only designed for heat meter applications and therefore not for the special requirements of cooling meters regarding condensation. This can have a very significant influence on the lifetime of the meter when applied within district cooling. At Kamstrup, we have more than 15 years of experience from installing our cooling meters in hot and humid environments like the Middle East. Our latest generation of cooling meters has therefore been designed to have a high immunity against intrusion of water when operating in hot and humid environments.

The degree of protection of a product against intrusion of water and dust can be determined using the product’s Ingress Protection code or IP code. The IP code consists of two digits, e.g. IP68. The first digit can be between 0 and 6, where 0 is no protection against dust and 6 is a dust-tight product. The second digit can be between 0 and 8, where 0 is no protection of ingress of water and 8 means that ingress of water in large quantities causing harmful effects is not possible, even when the enclosure of the product is continuously immersed in water as specified by the manufacturer. For all Kamstrup products, the IP code is determined as part of the type testing process required prior to approval. The IP code of a specific product can thus always be found on the MID or Danish cooling approval of the product, which is issued by an independent public authority.

Kamstrup ULTRAFLOW® 44 is a flow sensor specifically developed for cooling meters. It contains a unique solution in which the electronics are moved away from the pipe with chilled water where condensation occurs and are instead placed on the cable. Thereby, it is avoided to have DC voltage close to the condensation and this stops the intrusion of salts into the electronics. Kamstrup ULTRAFLOW® 44 has an IP68 approval and its robustness can be seen by the fact that it can be used in underground applications where the flow sensor is completely submerged for up to 2 months. Kamstrup ULTRAFLOW® 44 has the same great accuracy and long-term stability as all other Kamstrup ULTRAFLOW® products, but is also available in a special version with documented accuracy of ± 0.5 % at nominal flow qp.

The new Kamstrup TemperatureSensor 63 & 83 are the ideal choice as temperature sensors for cooling meters. TemperatureSensor 63 products are 2-wire temperature sensors while TemperatureSensor 83 products are 4-wire temperature sensors. Both TemperatureSensor 63 & 83 have an IP68 approval which is unique for temperature sensors used for cooling meters. The great durability in environments where condensation occurs comes from the fact that TemperatureSensor 63 & 83 are produced on a fully automatic production line that makes it possible to very precisely control several key parameters. For instance, ultra-precisely dosed heat paste protects the Pt500 sensor element by avoiding air in the thermal heat paste. The correct crimp of the metal sheath on the cable, which is critical towards reducing ingress of water, is also performed with high precision. The unique design of TemperatureSensor 83, by which the pocket and the connection head have been built together to form a tight enclosure of the temperature sensor, protects both the pocket, temperature sensor and the connection head from ingress of water.

To sum up

Based on 15 years of experience from the Middle East and Asia-Pacific, all Kamstrup cooling meters are designed to be used in hot and humid environments where significant condensation occurs. Both ULTRAFLOW® 44 and TemperatureSensor 63 & 83 are unique with their IP68 approvals and together with MULTICAL® 603, they create a cooling meter with a long lifetime and low total cost of ownership. Read more about the complete cooling meter solution.